One of the most well-known logos for engineering is a set of gears. Do you know what they do, how they work, or how they play into our lives? Today, we are going to dive into quite possibly the most famous mechanical device ever, the gear, and learn about some of the exciting careers that use them every day!

What is a Gear?

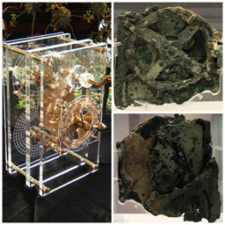

As far back as 300 B.C, Greek engineers used gears to estimate the sun’s position with a device called the Antikythera mechanism, the most advanced use of gears of its time. Fast-forward over 2000 years, today we build gears into almost all mechanical devices, from cars and bikes to even cellos! But how does a cylinder with teeth have the ability to change technology as we know it? The answer may be more straightforward than you think.

Image of Antikythera Mechanism borrowed from NovoScriptorium.com

Gears change the direction an object is moving. Whether it is from left to right, up to down, or counterclockwise to clockwise, gears can do it all. This characteristic might not sound special at first, but a refresher on elementary physics can remind us why this is unique. Isaac Newton, one of the most influential scientists of the 17th century, stated that all objects in motion stay in motion unless disturbed by another force. For example, a ball will continue to roll down a hill until friction slows it down to a stop or until another object interferes with its motion. However, we would never expect the ball to roll back up. This is also because of friction, as well as gravity. Gears have the unique ability to change the strength and direction of an applied force, or a force created intentionally by a person or object, something that rarely occurs in nature. As engineers, we constantly try to alter what happens naturally to make it work for us rather than against us. If we look at the previous example again, a mechanical engineer might find it helpful for that ball to roll back up the hill. They could accomplish this by engineering a gear system. Let us investigate how this could work.

How Does a Gear Work?

Gears are essentially a circle with rectangles around the edge, spaced evenly throughout the entire shape. These evenly spaced rectangles are teeth, and they make all the magic happen. One gear cannot do much, but amazing things can happen when we use multiple gears together. When two gears connect, the teeth of one gear connect with the space between the teeth in the other gear, and then the gears are ready to get to work.

Gears are essentially a circle with rectangles around the edge, spaced evenly throughout the entire shape. These evenly spaced rectangles are teeth, and they make all the magic happen. One gear cannot do much, but amazing things can happen when we use multiple gears together. When two gears connect, the teeth of one gear connect with the space between the teeth in the other gear, and then the gears are ready to get to work.

The unique thing about gears is that when one spins clockwise, the other spins counterclockwise. You might also notice that some gears spin faster than other gears. But how?

Several factors determine how gears operate. The first is gear size. We are talking about the radius or the length from the gear center to the edge. You may notice that gears with smaller radii spin faster than gears with larger radii. This is made possible by a series of events. First, for a gear system to work, the interlocking teeth must be the same size and have the same amount of space between them. This also means that the smaller gear has fewer teeth than the larger gear. Because the smaller gear has fewer teeth, its gear must spin faster to stay interlocked. Essentially, the smaller gear is using speed to make up for having fewer teeth. What if two gears are the same size? In that case, they will spin at the same speed because neither gear needs to use speed to make up for a difference in the number of teeth. Therefore, we can say that the speed of the smaller gear is always greater than the speed of the larger gear.

Another unique aspect of gears is torque relationships. In a nutshell, torque is the force that makes the gear spin. Just like speed, the torque also has a connection to size. However, unlike speed, the torque applied by larger gears will always be greater than torque applied by smaller gears. There is always some give and take in the relationships between torque, speed, and gear size. As gears increase size, torque must also increase at the sacrifice of speed. Picture biking up a steep hill. When you switch your bike into first gear, pedaling becomes more manageable because it takes less torque to move the pedal. This is only possible if you sacrifice speed, which is why it takes so long to bike up a steep hill when you shift into a lower gear. [LS2] With these relationships in mind, engineers can determine which size gears will do the job for specific tasks. A mechanical engineer at a bike manufacturing company uses gears to help design bikes. For example, an engineer would need to know what gear size and speeds work the best for an off-road bike because the same size and speed might not work for a street bike.

STEM Career Spotlight: Engineering

Now, what can we do with all this knowledge of gears? For starters, if you are interested in engineering, you are way ahead of the game! Mechanical engineers use gears to create airplanes, cars, bikes, boats, and so much more. Alternatively, a biomedical engineer might incorporate gears into hydraulic pumps, medical equipment, and prosthetics.

Ritu Raman at work

Another real-life example is that of a biomedical engineer at MIT, Ritu Raman. Her job is to create skeletal muscle cells that make robots walk. This would not be possible without gears in the robots’ knee joints, ankle joints, or anywhere else—they are a critical part of the equation. Ritu must account for gears and their torque and size to ensure her engineered skeletal muscle cells assist the movement of gear mechanisms in the best way possible.

The world as we know it would not work without gears. The next time you see a gear system at work, think about the centuries of science behind them!

Nathan Green is a summer intern for the Programs Team at the Connecticut Science Center. He is currently studying Biomedical Engineering at the University of Hartford. He one day hopes to contribute to NASA’s mission to colonize Mars with the help of biotechnology or to advance research in tissue engineering. Prior to joining the Science Center, Nathan worked in childcare.